-

-

Profiles and Bars are produced according to customer requirements in special sizes and forms with many years of production experience according to EN 12167 European standard.

Production for profiles and bars is divided into two parts as extruded or cold drawn according to the required dimensional tolerances and mechanical properties.- Alloys

- Production Ranges

- Tolerances

- Ordering Information

-

- Download

- Product Code

- EN Symbol

- EN No

- ASTM

-

-

- S600

- CuZn35Pb1

- CW600N

- C34000

-

-

- S605

- CuZn37Pb1

- CW605N

- C35000

-

-

- S606

- CuZn37Pb2

- CW606N

- C35300

-

-

- S607

- CuZn38Pb1

- CW607N

- C37000

-

-

- S610

- CuZn39Pb0,5

- CW610N

- C36500

-

-

- S611

- CuZn39Pb1

- CW611N

- -

-

-

- S627

- CuZn40Pb1

- CW627N

- -

- (*) please contact us for other alloys.

-

Size (mm) Weight (kg/m) Size (mm) Weight (kg/m) Size (mm) Weight (kg/m) Size (mm) Weight (kg/m) 7 x 9 0,53 10 x 14 1,18 12.6 x 17.8 1,88 20 x 35 5,88 7 x 50 2,96 10 x 15 1,26 12.6 x 50.7 5,4 20 x 37 6,22 7.6 x 9.28 0,59 10 x 16 1,35 12.68 x 28.6 3,05 20 x 40 6,72 8 x 10 0,67 10 x 17.45 1,47 12.7 x 19.05 2,03 20 x 45 7,56 8 x 12 0,81 10 x 18 1,52 12.7 x 25.4 2,71 20 x 50 8,4 8 x 13 0,88 10 x 20 1,68 12.7 x 38.1 4,09 20 x 60 10,08 8 x 15 1,01 10 x 23 1,93 12.7 x 50.8 5,45 20 x 70 11,76 8 x 16 1,08 10 x 24 2,03 14.5 x 26.5 3,25 20,2 x 30 5,09 8 x 18 1,22 10 x 25 2,1 14.6 x 17.8 2,2 22 x 26 4,81 8 x 20 1,34 10 x 30 2,52 15 x 16 2,03 22.23 x 50.8 9,49 8 x 23 1,55 10 x 33.5 2,81 15 x 20 2,52 25 x 30 6,3 8 x 25 1,68 10 x 35 2,94 15 x 25 3,15 25 x 33.62 7,1 8 x 30 2,02 10 x 40 3,36 15 x 30 3,78 25 x 35 7,35 8 x 32 2,15 10 x 45 3,78 15 x 35 4,41 25 x 40 8,4 8 x 35 2,35 10 x 50 4,2 15 x 40 5,04 25 x 45 9,45 8 x 40 2,69 10 x 60 5,04 15 x 45 5,67 25 x 50 10,5 8 x 45 3,02 10.5 x 55 4,88 15 x 50 6,3 25 x 60 12,6 8 x 50 3,36 10.8 x 17.8 1,62 15 x 60 7,56 25.4 x 50.8 10,84 8 x 60 4,03 12 x 15 1,51 15.86 x 38 5,06 26 x 46 10,05 8.32 x 32 2,24 12 x 17 1,71 15.88 x 25.4 3,39 28 x 30 7,06 8.83 x 23.43 1,75 12 x 17.8 1,8 15.88 x 31.75 4,24 30 x 35 8,87 9 x 13 0,99 12 x 20 2,02 15.88 x 50.8 6,82 30 x 40 10,08 9 x 33 2,5 12 x 25 2,52 16 x 19 2,55 30 x 45 11,41 9 x 60 4,54 12 x 30 3,02 16 x 46 6,18 30 x 50 12,6 9.53 x 12.7 1,02 12 x 32 3,23 18 x 32 4,84 30 x 60 15,12 9.53 x 15.88 1,27 12 x 35 3,53 18 x 35 köşe R1 5,29 32 x 37 10 9.53 x 19.05 1,53 12 x 35.5 3,6 19 x 38 6,1 33 x 56 15,62 9.53 x 25.4 2,03 12 x 40 4,03 19.05 x 25.4 4,07 35 x 40 11,83 9.53 x 31.75 4,26 12 x 45 4,54 19.05 x 31.75 5,11 35 x 45 13,31 9.53 x 38.1 3,07 12 x 50 5,04 19.05 x 38,1 6,1 35 x 50 14,7 9.53 x 50.8 4,09 12 x 60 6,05 19.05 x 38.1 6,1 38.1 x 50.8 16,35 9.7 x 19.7 1,61 12.1 x 25 2,56 19.05 x 44.45 7,16 40 x 50 16,8 9.75 x 10.75 0,87 12.1 x 25.6 2,62 19.05 x 50.8 8,13 40 x 60 20,16 9.8 x 10.8 0,89 12.5 x 14 1,47 20 x 25 4,2 42 x 48 17,04 10 x 12 1,01 12.6 x 17.75 1,85 20 x 30 5,04 - - please contact us for other sizes.

-

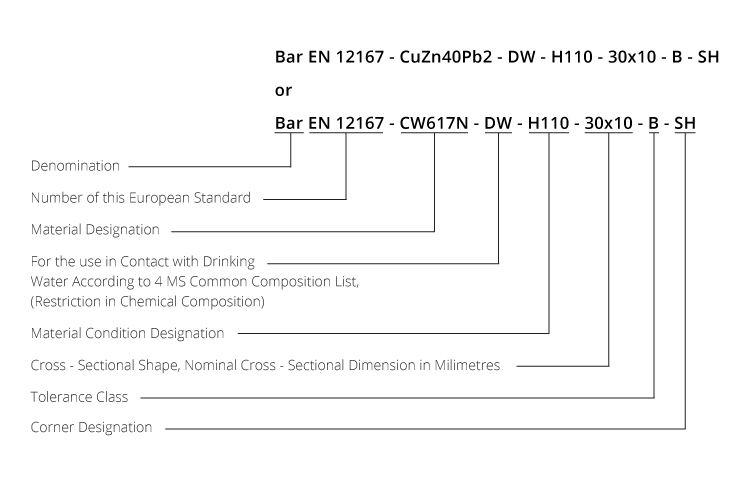

Ordering information for profiles and bars is defined according to EN 12167 European Standart. This definition is as follows:

- Naming

- Profiles or Bars

- Standard

- EN 12167

- Material Designation

- Alloy Symbol or Number, E.g. CuZn40Pb2 or CW617N

- Materials to be used in Drinking Water

- When specified as DW, production is carried out according to the restrictions on 4MS and UBA list

- Material Condition Designation

- he necessary mechanical properties if different than M, E.g. Hardness value min. H110 for 110 HBW

- Nominal Cross-sectional Dimension

- The number of sections for profiles or detailed technical drawing with tolerances. Cross sectional dimensions (thickness x width) for rectangular section bars

- Tolerances

- Class A,B or C

- Corner Type

- When necessary, E.g. SH - Sharp or RD - Rounded

Bar conforming to this standard, in material designated either CuZn40Pb2 or CW617N for drinking water applications according to 4MS Common Composition List, in material condition H110, nomial cross-sectional dimensions 30 mm x 10 mm, tolarence Class B, with sharp corners, shall be designated as follows:

The product designation provides a standardized pattern of designation of the main order information when combined with quantity, length / piece and weight tolerances. Additional order information may include; the test method, the type of packaging information and quality assurance certification.

-

*Dimensions are in millimeters (mm)EN 12167 - Tolerances on Width and Thickness of Bar Nominal Width Tolerance on Width Tolerance on Thickness for Range of Thickness Over Up to and inc. Over 5 up to and including 6 Over 6 up to and including 10 Over 10 up to and including 18 Over 18 up to and including 30 Over 30 up to and including 50 6Inc. 18 ±0,10 ±0,07 ±0,09 ±0,10 - - 18 30 ±0,15 ±0,07 ±0,09 ±0,10 ±0,15 - 30 50 ±0,20 ±0,09 ±0,10 ±0,12 ±0,15 ±0,20 50 70 ±0,25 ±0,11 ±0,12 ±0,15

±0,20 ±0,25

-