-

-

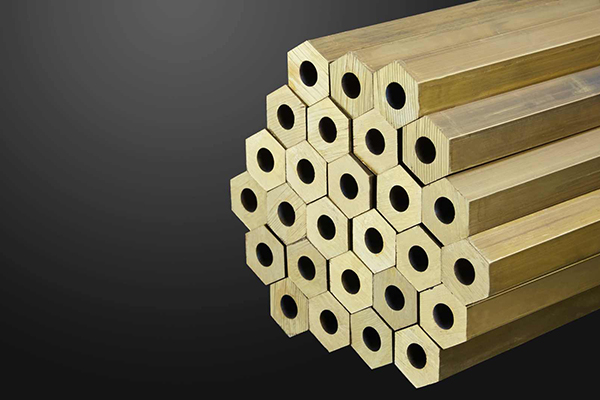

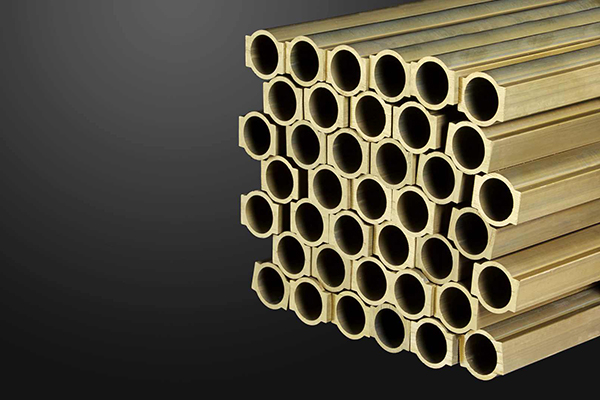

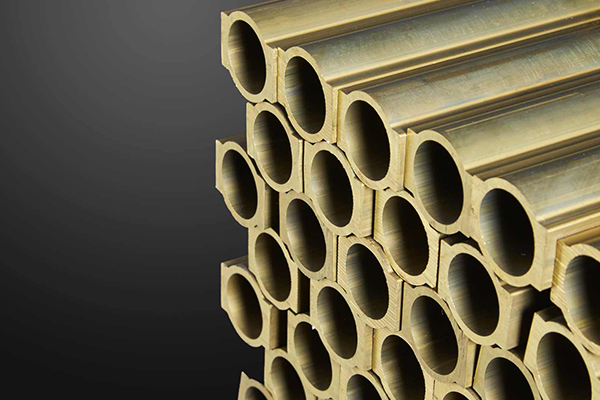

Hollow Rods are produced according to EN 12168 European Standard.

It is enable to less tool wear, less material consumption and metal loss by decreasing drilling and processing costs to the lowest.

Stress relieving process is an indispensable part of hollow rod production. After the hollow rod production stress relieving process is applied as a standard process.

- Alloys

- Production Ranges

- Tolerances

- Ordering Information

- Manifolds

-

- Download

- Product Code

- EN Symbol

- EN No

- ASTM

-

-

- S600

- CuZn35Pb1

- CW600N

- C34000

-

-

- S605

- CuZn37Pb1

- CW605N

- C35000

-

-

- S606

- CuZn37Pb2

- CW606N

- C35300

-

-

- S607

- CuZn38Pb1

- CW607N

- C37000

-

-

- S610

- CuZn39Pb0,5

- CW610N

- C36500

-

-

- S611

- CuZn39Pb1

- CW611N

- -

-

-

- S627

- CuZn40Pb1

- CW627N

- -

- (*) please contact us for other alloys.

-

Designation Cold Drawn Extruded Cold Drawn Hexagon Extruded Hexagon Cold Drawn Octagon Extruded Octagon Round and Polygons Standards External Diameter (mm) Width Across-flats (mm) Width Across-flats (mm) Internal Diameter (mm) Wall Thickness (mm) Product Code EN Symbol EN No ASTM Min Max Max Min Max Max Min Max Max Min Max Min Max S509 CuZn40 CW509L C27450 23 78 80 22 65 77 23 60 75 13 59 3 25 S510 CuZn42 CW510L C28500 23 78 80 22 65 77 23 60 75 13 59 3 25 S511 CuZn38As CW511L C27453 23 78 80 22 65 77 23 60 75 13 59 4 25 S600 CuZn35Pb1 CW600N C34000 23 78 80 22 65 77 23 60 75 13 59 4 25 S602 CuZn36Pb2As CW602N C35330 23 78 80 22 65 77 23 60 75 13 59 4 25 S603 CuZn36Pb3 CW603N C36000 23 78 80 22 65 77 23 60 75 13 59 4 25 S605 CuZn37Pb1 CW605N C35000 23 78 80 22 65 77 23 60 75 13 59 4 25 S606 CuZn37Pb2 CW606N C35300 23 78 80 22 65 77 23 60 75 13 59 4 25 S607 CuZn38Pb1 CW607N C37000 23 78 80 22 65 77 23 60 75 13 59 4 25 S608 CuZn38Pb2 CW608N - 23 78 80 22 65 77 23 60 75 13 59 4 25 S610 CuZn39Pb0,5 CW610N C36500 23 78 80 22 65 77 23 60 75 13 59 3 25 S611 CuZn39Pb1 CW611N - 23 78 80 22 65 77 23 60 75 13 59 3 25 S612 CuZn39Pb2 CW612N C37700 23 78 80 22 65 77 23 60 75 13 59 3 25 S614 CuZn39Pb3 CW614N C38500 23 78 80 22 65 77 23 60 75 13 59 3 25 S617 CuZn40Pb2 CW617N C38000 23 78 80 22 65 77 23 60 75 13 59 3 25 S625 CuZn35Pb1,5AlAs CW625N - 23 78 80 22 65 77 23 60 75 13 59 4 25 S626 CuZn33Pb1,5AlAs CW626N - 23 78 80 22 65 77 23 60 75 13 59 4 25 S627 CuZn40Pb1 CW627N - 23 78 80 22 65 77 23 60 75 13 59 3 25 Ecobrass CuZn21Si3P CW724R C69300 23 78 80 22 65 77 23 60 75 13 59 4 25 S725 CuZn33Pb1AlSiAs CW725R - 23 78 80 22 65 77 23 60 75 13 59 4 25 Globrass CuZn36Si1P CW726R C68370 23 78 80 22 65 77 23 60 75 13 59 4 25 S727 CuZn35Sn1P CW727R - 23 78 80 22 65 77 23 60 75 13 59 4 25 S713 CuZn37Mn3AI2PbSi CW713R C67420 23 78 80 22 65 77 23 60 75 13 59 4 25

-

Ordering information for hollow rods is defined according to EN 12168 European Standart. This definition is as follows:

- Naming

- Hollow Rod

- Standard

- EN 12168

- Material Designation

-

Alloy Symbol or Number,

E.g. CuZn40Pb2 or CW617N

- Materials to be used in Drinking Water

- When specified as DW, production is carried out according to the restrictions on 4MS and UBA list

- Material Condition Designation

-

The necessary mechanical properties if different than M,

E.g. Hardness value min. H110 for 110 HBW

- Cross-sectional Shape

- E.g. RND for round, SQR for square, HEX for hexagonal, OCT for octagonal, RCT for rectangular (bar), PFL for profile

- Nominal Cross-sectional Dimension

- External dimension30 for 30 mm and internal dimension 20 for 20 mm

- Tolerances

-

External- Cold Drawn (Class B tolerance) x Internal-Extruded (Class A tolerance)

External- Cold Drawn (Class C tolerance) x Internal- Cold Drawn (Class B tolerance)

External- Extruded (Class A tolerance) x Internal- Extruded (Class A tolerance)

- Corner Type

- When necessary, E.g. SH - Sharp or RD - Rounded

- Eccentricity

- 10% (max)

Hollow rod for free machining purposes conforming to this standart, in material designated either CuZn40Pb2 or CW617N, for drinking water applications according to 4MS Common Composition List, in material condition H090, hexagonel external shape, 60 mm nominal width across-flats dimension, tolerance Class A, round bore of nomial diameter 20 mm, tolerance Class B sharp corners, shall be designated as follows:

The product designation provides a standardized pattern of designation of the main order information when combined with quantity, length / piece and weight tolerances. Additional order information may include; the test method, the type of packaging information and quality assurance certification.

-

Standard EN 12168 Nominal External Diameter or Width Across-flats Tolerances on Diameter or Width Across-flats Tolerance on Hole Round Tolerance on Hole Hexagon Over Up to and inc. Class A Class B Class C Class A Class B - 13 18 - - - ±0,35 - +0,70

-018 20 - - - ±0,42 - +0,84

-020 23 - 0

-0,21- ±0,42 ±0,17 +0,84

-023 26 - 0

-0,21- ±0,42 ±0,17 +0,84

-026 30 - 0

-0,210

-0,13±0,42 ±0,17 +0,84

-030 50 - 0

-0,25

0

-0,16±0,80 ±0,20 +1,6

-050 55 - 0

-0,460

-0,3±0,95 ±0,37 - 55 65 ±0,60 0

-0,460

-0,3±0,95 - - 65 80 ±0,60 0

-0,460

-0,3- - -

-

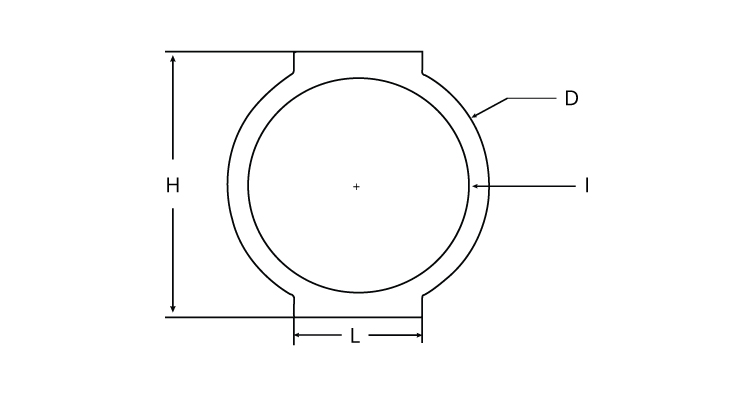

Sarbak Metal Manifold Profile Dimensions and Tolerances 3/4" Normal Manifold 3/4" Light Manifold 3/4" Ic Disli Manifold 35X27 Manifold Alloy CW614N CW614N CW614N CW614N Top (L1) 24 +0,05/ -0,20 18 +0,05/ -0,20 16 +0,05/ -0,20 27 +0,20/ -0 Bottom (L2) 24 +0,05/ -0,20 18 +0,05/ -0,20 24 +0,05/ -0,20 27 +0,20/ -0 Height (H) 35 +0,10/ -0,35 32 +0,10/ -0,35 24 +0,10/ -0,35 35 +0,10/ -0,35 Outer Dia (D) 31 ±0,20 30 ±0,20 31 ±0,20 32 ±0,20 Inner Dia (I) 24,4 ±0,20 24 ±0,20 24 ±0,20 23 ±0,20 Weight( Kg / m) 3,92 2,73 3,66 4,94 Eccentricity (Max) 10% 10% 13% 10% 1" Normal Manifold 1" B Manifold 1" Light Manifold 1" Ic Disli Manifold Alloy CW614N CW614N CW603N CW614N Top (L1) 24 +0,05/ -0,20 24 +0,05/ -0,20 18 +0,10/ -0,20 18 +0,05/ -0,20 Bottom (L2) 24 +0,05/ -0,20 24 +0,05/ -0,20 18 +0,10/ -0,20 21 +0,05/ -0,20 Height (H) 41 +0,10/ -0,35 41 +0,10/ -0,35 38 +0,10/ -0,35 40,1 ±0,10 Outer Dia (D) 37,5 ±0,20 36,5 ±0,20 37 ±0,20 37,15 ±0,20 Inner Dia (I) 30,5 ±0,20 30,5 ±0,20 30,5 ±0,20 30 ±0,20 Weight( Kg / m) 4,40 4,13 3,31 3,95 Eccentricity (Max) 10% 10% 10% 13% 1"KL6 Manifold 1" Dıs Disli Manifold 1" Disi Manifold 1" İc Disli Manifold Alloy CW614N CW614N CW614N CW614N Top (L1) 16 +0,05/ -0,20 16 +0,05/ -0,20 16 +0,05/ -0,20 16 +0,05/ -0,20 Bottom (L2) 24 +0,05/ -0,20 24 +0,05/ -0,20 24 +0,05/ -0,20 24 +0,05/ -0,20 Height (H) 39 +0,10/ -0,35 37 +0,10/ -0,35 40,5 +0,10/ -0,35 40 +0,10/ -0,35 Outer Dia (D) 37 ±0,20 34 ±0,20 37,5 ±0,20 36,5 ±0,20 Inner Dia (I) 30,5 ±0,20 27 ±0,20 30 ±0,20 30 ±0,20 Weight( Kg / m) 3,59 3,72 4,20 3,81 Eccentricity (Max) 13% 13% 13% 13% 1" Elight Manifold 1 1/4" Normal Manifold 1 1/4" Light Manifold Alloy CW614N CW614N CW614N Top (L1) 25,3 +0/ -0,30 24 +0,05/ -0,20 18 +0,05/ -0,20 Bottom (L2) 25,3 +0/ -0,30 24 +0,05/ -0,20 18 +0,05/ -0,20 Height (H) 39 ±0,20 51 +0,10/ -0,35 48 +0,10/ -0,35 Outer Dia (D) 37 ±0,20 47 ±0,20 46 ±0,20 Inner Dia (I) 30,6 ±0,20 39 ±0,20 39,5 ±0,20 Weight( Kg / m) 3,94 5,77 4,15 Eccentricity (Max) 10% 10% 10% 1 1/4" İcten Disli Manifold 1 1/2"Manifold 1" 20x20 Manifold Alloy CW614N CW614N CW603N Top (L1) 18 +0,05/ -0,20 25 +0,05/ -0,20 20 +0,05/ -0,20 Bottom (L2) 21 +0,05/ -0,20 25 +0,05/ -0,20 20 +0,05/ -0,20 Height (H) 50 +0,10/ -0,35 57 +0,10/ -0,35 38 +0,10/ -0,35 Outer Dia (D) 46 ±0,20 53,2 ±0,20 37 ±0,20 Inner Dia (I) 39 ±0,20 44,8 +0/-0,4 30,8 ±0,20 Weight( Kg / m) 4,82 6,65 3,20 Eccentricity (Max) 10% 10% 10% S19 Manifold S20 Manifold S21 Manifold Alloy CW603N CW603N CW603N Top (L1) 24 +0,10/ -0,20 24 +0,10/ -0,20 24 +0,10/ -0,20 Bottom (L2) 24 +0,10/ -0,20 24 +0,10/ -0,20 24 +0,10/ -0,20 Height (H) 37 +0,10/ -0,35 30,5 +0,10/ -0,35 46,5 +0,10/ -0,35 Outer Dia (D) 36,5 ±0,20 30 ±0,20 46 ±0,20 Inner Dia (I) 30,8 ±0,20 24,4 ±0,20 39,5 ±0,20 Weight( Kg / m) 3,22 2,87 4,26 Eccentricity (Max) 10% 10% 10%

-